PermaBond UVFS Patch Specifications

Introducing PermaBond® with UV Fusion Sealant (UVFS) – The Only Structural Repair Solution

PermaBond® with UV Fusion Sealant (UVFS) is the pinnacle of advanced repair technology, meticulously designed to address the most demanding structural needs. With its superior sheet lamination and rapid UV curing mechanism, PermaBond® offers unmatched durability and resilience. This highly innovative product is engineered for a variety of applications, ensuring reliable and long-lasting repairs across metal, wood, plastic, and fiberglass surfaces. Equipped with outstanding technical properties, PermaBond® guarantees performance under extreme conditions, providing a dependable solution that delivers immediate customer satisfaction on the first call.

PERMABOND® THE ONLY STRUCTURAL REPAIR

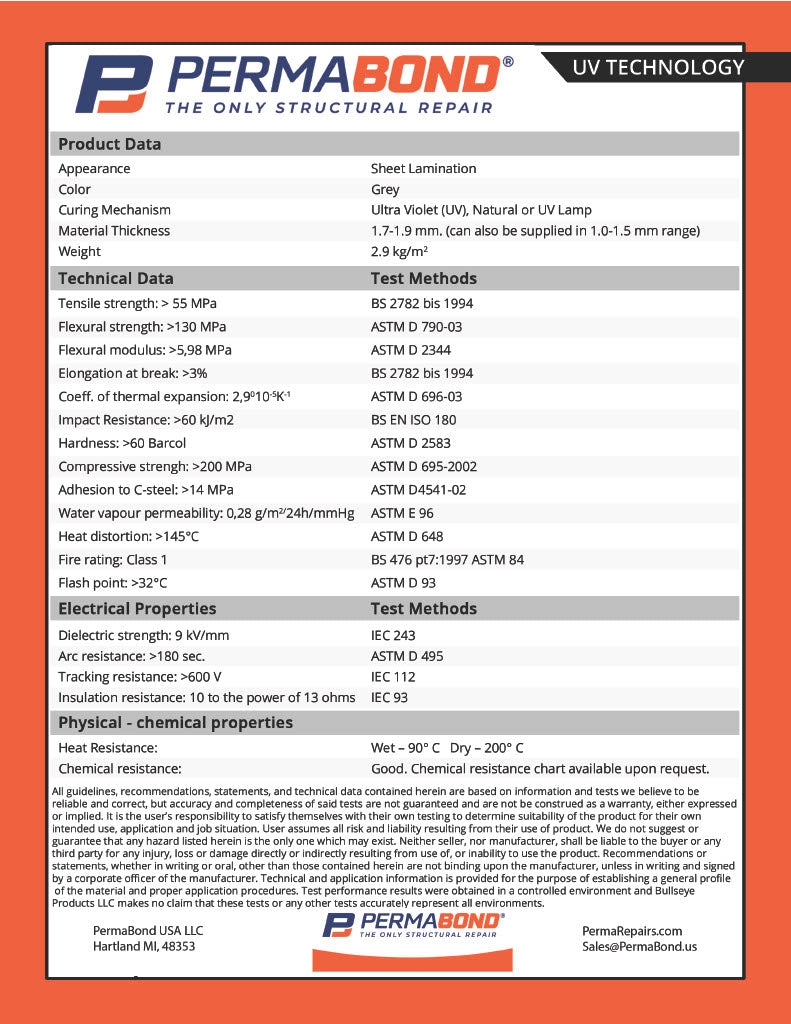

Product Data

Appearance:

Sheet Lamination

Color: Grey

Curing Mechanism: Ultra Violet (UV), Natural or UV Lamp

Material Thickness: 1.7-1.9 mm. (can also be supplied in 1.0-1.5 mm range)

Weight: 2.9 kg/m²

Technical Data | Test Methods

Tensile strength: > 55 MPa | BS 2782 bis 1994

Flexural strength: >130 MPa | ASTM D 790-03

Flexural modulus: >5.98 MPa | ASTM D 2344

Elongation at break: >3% | BS 2782 bis 1994

Coeff. of thermal expansion: 2.910⁻⁵K⁻¹ | ASTM D 696-03

Impact Resistance: >60 kJ/m² | BS EN ISO 180

Hardness: >60 Barcol | ASTM D 2583

Compressive strength: >200 MPa | ASTM D 695-2002

Adhesion to C-steel: >14 MPa | ASTM D4541-02

Water vapour permeability: 0.28 g/m²*24h/mmHg | ASTM E 96

Heat distortion: >145°C | ASTM D 648

Fire rating: Class 1 | BS 476 pt7:1997 ASTM 84

Flash point: >32°C | ASTM D 93

Electrical Properties | Test Methods

Dielectric strength: 9 kV/mm | IEC 243

Arc resistance: >180 sec. | ASTM D 495

Tracking resistance: >600 V | IEC 112

Insulation resistance: 10 to the power of 13 ohms | IEC 93

Physical - chemical properties

Heat Resistance:

- Wet - 90°C

- Dry - 200°C

- Chemical resistance: Good.

Chemical resistance chart available upon request.